Oz Machine ALCOR – II C CNC Controlled Profile Machining and Cutting Center (8 Axis)

Oz Machine ALCOR – II C CNC Controlled Profile Machining and Cutting Center (8 Axis)

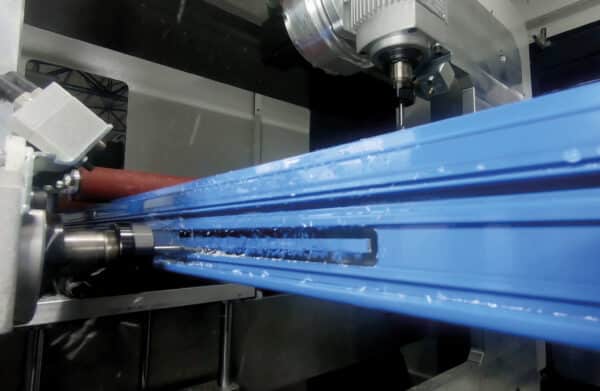

Used for cutting, milling, punching, marking and drain channel opening processes on 4 surfaces of aluminum and PVC profiles.

Used for cutting, milling, punching, marking and drain channel opening processes on 4 surfaces of aluminum and PVC profiles.

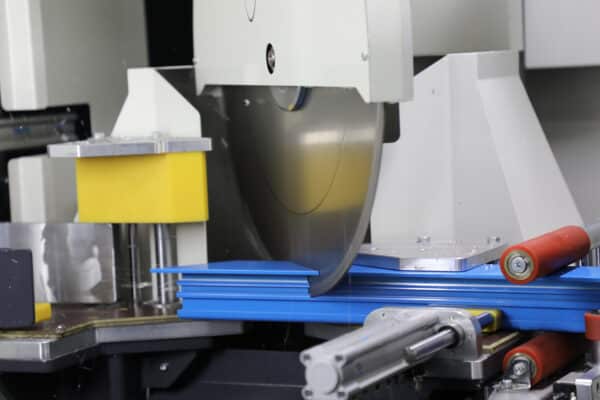

- Servo controlled cutting

- Servo controlled rotation axis

- Automatic positioning at all degrees between 30° and 150° with servo motion system

- Pneumatic holder robot with servo axis control and manual adjustment feature for accurate positioning of profiles

- Industrial PC with Windows based touchscreen and easy to use practical interface

- Remote access

- Data transfer over remote network connection, Ethernet and USB

- Guard cabin for cutting and machining area

- Adjustable saw blade travel speed

- Discharge unit with pneumatic conveying system

- Feeding capacity for 10 profiles

- High cutting capacity to increase efficiency

- High speed axis movements

- Automatic lubrication in processing area

- Ability to process 4 different surfaces of a profile

- Ability to use cutting and processing units independently