Epk 4000 Casement Assembly Center

Epk 4000 Casement Assembly Center

Innovative and highly efficient accessory drilling and screwing station for corner and truss bed frames

- Innovative and highly efficient accessory drilling and screwing station for corner and truss bed frames

- Fast and precise work – this machine provides a surprising increase in productivity in window manufacturing

- Thanks to its easy use and ergonomically designed workflow, corner truss beds can be drilled, fitted and screwed by an employee

- Thanks to the movable support system, it is not necessary to drill the connection and screw holes using a template

- Unit can be rotated 90 ° for the machining of multi-leaf frames

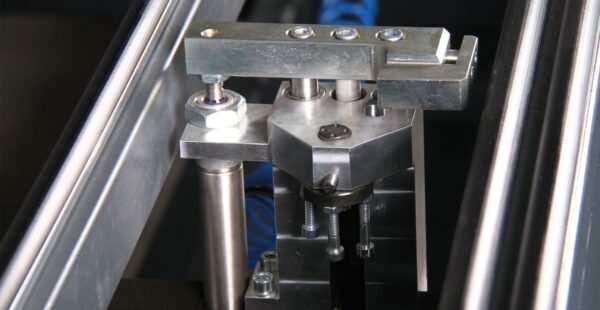

- The adjustment device used to drill the bearing shaft in the Y-direction in multi-wing frames can be positioned by means of raster dimensions

- With the screwing feeder that can be moved manually on the horizontal and slide slide, the corner truss beds are screwed to the closed frames

- Unit; It is equipped with an automatic screw feed, a screwdriver turbine for screwing in self-tapping bolts and a pneumatic screw-depth stop.

- Pneumatic frame clamping and positioning device can be moved on the center of the table

- Possible frame duct sizes are between 360 and 3,400 mm

- 2 pneumatic duct stoppers that can be lowered with the turret for 4 different frame installation depths

- Laser assembly to show the screwing location

- Bench length 4.040 mm

- Bench width 1.700 mm

- Total length: 4.220 mm

- Total width: 2.010 mm

- Height 1.720 mm

- Bench height can be adjusted between 950 – 1.050 mm

- Min. frame size 560 x 200 mm

- Max. frame size 3,800 x 1,700 mm

- Min. profile height 54 mm

- Max. profile height: 110 mm

- Weight 650 kg

- Air pressure: 7 bar

- Air consumption:

- Screwdriver approx. 250 l / min.

- Clamping device approx. 40 l / min.